The Dominion Post published Ladder fall victim’s private prosecution after WorkSafe refused to charge 30th March 2019, which was the follow-up article from Worker injured in Grenada North ladder fall still in intensive care, Apr 27 2016. The legal ramifications are intriguing; however, the key safety issues focus on basic ladder and forklift safety.

Here’s a rough summary of what happened:

- On April 20, 2016, Jayden Rickard-Simms was working as a refrigeration technician at the Grenada North site. The site was used by Goodman Fielder, Fonterra (Tip Top), and Halls Refrigerated Transport.

- Rickard-Simms was working in shared warehouse space de-icing an evaporator in a chiller. Allegedly a forklift that was being driven in and out of the chiller struck the ladder he was on.

- The forklift driver tooted his horn as he entered the curtained chiller entry, although he did not see Rickard-Simms until he looked behind him and saw him on the ground.

- Rickard-Simms spent two weeks in intensive care and is still affected by his injuries three years later.

- WorksafeNZ decided not to prosecute (for reasons unknown).

What’s the latest at the Courts?

- Rickard-Simms has filed papers in the Porirua District Court accusing Goodman Fielder and Halls Transport of offences under the Health and Safety at Work Act 2015.

- The District Court judge accepted the charging documents.

- A judge at the High Court in Wellington also dismissed an attempt by the two companies to stop the prosecution.

Why am I confused?

- If you are injured in NZ, you are covered by our ‘No Fault’ ACC scheme. A founding principle of the Accident Compensation Act 2001 is that based on the no blame/ we got your rehabilitation sorted you can’t sue people or business entities (even if their act of omission caused your accident).

- The one exception is that you can sue for ‘exemplary damages’ under the AC Act if someone was ‘grossly negligent’ (demonstrated particularly blatant and reckless behaviour).

- The Health and Safety at Work Act 2015 comes under the criminal jurisdiction i.e. it’s normally the crown (i.e. WorksafeNZ) bringing the prosecution. However, under S 144 when WorksafeNZ cannot, or chooses not to prosecute, a private prosecution can be initiated. Worksafe may choose not to prosecute (even if there is sufficient evidence) if it believes the prosecution is ‘not in the public interest’.

Ladder and Forklift Safety – What can you do at your site to stop an incident like this happening?

It’s a little hard to drill down into what actually happened due to the lack of information available; however, here are some basic ideas on how you can help prevent ladder falls or forklift incidents on your site.

Ladder Inventory and Inspections

- Either number your ladders or put the Licence plate number of the vehicle they belong to on the ladder so they are clearly identified and checked off.

- Ladders need informal checks every time they are used, and best practice says they need a monthly formal check and an annual engineering check according to AS/NZS 1892.1:1996 Portable ladders – Part 1: Metal.

Safe Use of Ladders

When setting up a ladder ensure it is:

- On sound and level ground.

- Set at the correct angle – > 1 in 4

- Of adequate length (minimum of 1 metre above landing).

- Held at the bottom or securely lashed at top

- Has stays secured if it is a folding ladder

When climbing a ladder:

- Use both hands and face the ladder while climbing.

- Beware of electrical hazards.

- Avoid over reaching out to move a ladder

Own Your Zone

- Best practice is to use cones and cone bars (bumblebee poles) to establish your work area and make sure no one is going to walk/drive through it.

- If there are other workers in the area, talk to them and explain what you are doing.

- Have designated pedestrian walkways and pedestrian exclusion zones where forklifts are operating. See WorksafeNZ’s WORKPLACE TRAFFIC MANAGEMENT Fact sheet and WorksafeNZ Traffic management in manufacturing

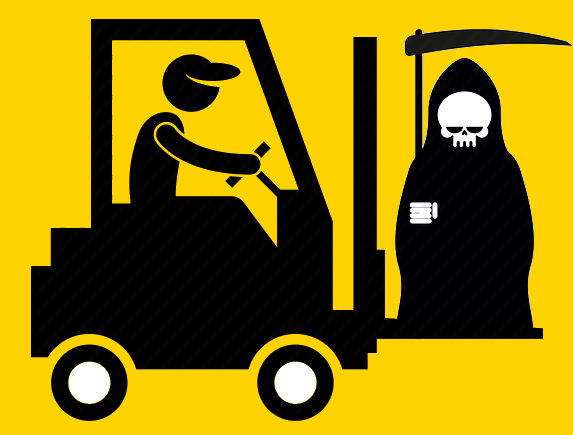

‘Powered Industrial Trucks’/ Forklifts a.k.a. Death on Wheels

From my experience forklift accidents tend to happen quickly and be either gruesome, deadly or both. If you have a forklift on site, get the basics right:

- Operators have the proper training and competency

- Where ever possible pedestrians are kept separate from the operating area

- Pre-operation checks are carried out

- The machine is driven at a speed that allows for safe breaking. See Monash University Accident Research Centre findings on emergency braking distances for typical forklifts on a level surface – based on a driver reaction time of 1.5 seconds at 14 km/hr = 5.8 metres

- Loads are secure within the forklift’s rated capacity

- Good housekeeping is maintained in the operating area

- Deficiencies or damage to the machine is reported immediately

If you have anything to add to the list of Ladder or Forklift Safety Basics 101 please call Sarah on 0272 007 680 or email sarah@employmenow.co.nz.

Have a safe and productive week.

SB